Craft fair stands and their finishes: survival manual for fairs /6

Let's talk about the finishes! This is where you really understand why a stand costs what it costs. When choosing one project over another, you have to check if the finishes do not represent a price difference. Are the floors carpeted or quality? Are the walls made of MDF or chipboard? Are the countertops melamine... or painted... we are going to review all these issues so that the next time you look at a budget... you understand what you are choosing

carpentry finishes

A- Painted chipboard trade fair stands

The painted chipboard is the most basic raw material in fair carpentry. It is usually painted with matte water-based plastic paint, which gives a somewhat porous finish. This makes it difficult to stick the self-adhesive graphics and, depending on the porosity, ends up peeling off. The paint requires drying, and during the times of the fair, which are not usually more than five days of assembly on average... it is usually the element that generates the most stress during assembly. If the paint doesn't dry in the right amount of time, the graphic always lifts. This is the biggest headache for the assemblers, as they have to produce new graphics on the fly and stick them many times during the show.

- Economic alternative for the construction of stands

- Commercial thicknesses: The commercial thicknesses of chipboard most used in Europe are 9 mm, 12 mm, 15 mm, 18 mm and 22 mm. These thicknesses are often used for furniture construction and interior design applications.

- Width: The standard width of chipboard panels is 1220mm, but wider panels of 1830mm and 2440mm are also available.

- Length: The standard length of chipboard panels is 2440mm, but longer 3050mm and 3660mm panels are also available.

B- Elements for exhibition stands made of DM

DM is a more compact and smooth material than chipboard. It is a bit more expensive and guarantees less porous surfaces.

Density: MDF is characterized by having a medium density, so it is denser than plywood and less dense than solid wood. The density can range between 600 and 800 kg/m³.

It is important to bear in mind that MDF is a material that does not resist excessive humidity or direct exposure to sunlight. Therefore, it is recommended to use it indoors and under controlled environmental conditions to ensure its durability.

Uniformity: MDF is made from pressed wood fibers joined with synthetic resins. The result is a uniform material in terms of density, texture and thickness. This uniformity makes it ideal for woodworking projects that require a smooth, even surface.

Ease of machining: MDF is a material that can be easily cut, drilled, sanded and painted. It can also be curved and shaped by heat or steam.

Thickness: The most common thicknesses of MDF panels are 3, 6, 9, 12, 16, 18 and 22 mm.

MDF boards can be found in different sizes, but are usually made in 2440mm x 1220mm sheets.

C- Elements for fair stands made on a pine frame with stretched canvas

In many stands, stretched textiles are used instead of rigid panels. This makes the construction much lighter and more sustainable. It is usually used in air volumes

- Excellent alternative to reduce weight (usually used in air volumes).

- Allows the construction of unpainted walls

- It is a very sustainable alternative because it reduces the amount of waste

In this case, the stand has practically no other carpentry than the rear wall and its frames. The graphic dresses the stand

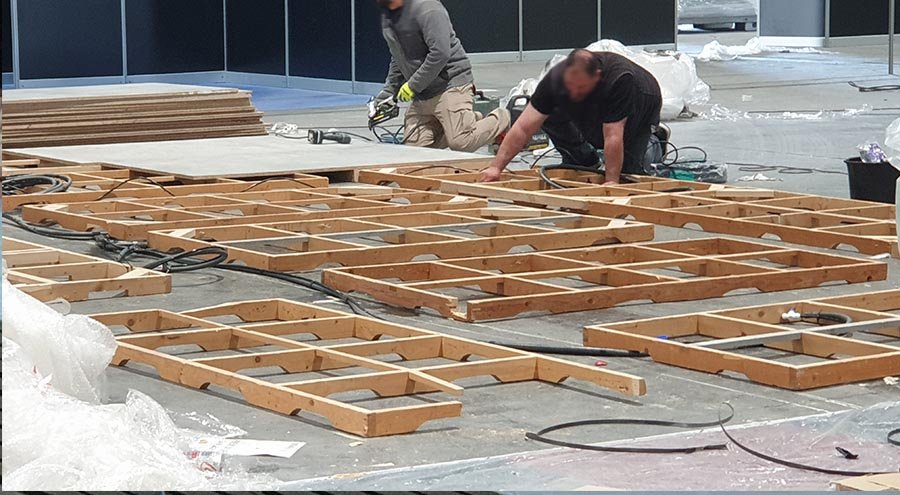

D- Elements of exhibition stands made of pine/mdf and plywood frames

Plywood is a very light material that is also used for high volumes;

Composition: Plywood is made up of several thin layers of wood, usually from deciduous trees, with the grain direction alternating in each layer to increase its strength and stability.

Resistance: Plywood is a very resistant and durable material. Its resistance to warping and cracking is greater than that of solid wood, making it ideal for projects that require high strength.

Ease of machining: Plywood can be easily cut, drilled, sanded, and painted. It can also be curved and shaped by heat or steam.

Thickness: The most common thicknesses of plywood vary depending on the manufacturer and country, but usually range from 2.5mm to 25mm. Some of the most common thicknesses are:

2.5mm, 3.2mm, 4mm, 6mm, 9mm, 12mm, 15mm, 18mm, 22mm, 25mm

Plywood can be found in different sizes, but is generally made in 2440mm x 1220mm sheets.

E- Elements for exhibition stands made with sustainable recycled materials

Both OBS wood and the option of using cardboard are interesting possibilities when it comes to making your stand more sustainable. A widely used option is tubes of different thicknesses, as well as cardboard boxes configuring totem poles and walls.

- Material: The OBS is made of wood chips oriented in different directions and bonded with synthetic resins, making it strong and durable.

- Thickness: OBS can be found in different thicknesses, from 6mm to 30mm or more, depending on the needs of the project.

- Size: OBS panels can be found in different sizes, but are generally made in 2440mm x 1220mm sheets.

- Ease of Cutting: OBS is easy to cut and shape, allowing it to be used in a wide variety of woodworking projects.

F- Exhibition stands made with melamine boards

Melamine is an excellent finish for fair stands. The appearance of a stand made of melamine is clean and well finished. The cost is higher than MDF or chipboard, but has the advantage of removing paint.

- Melamine is a superior finish to paint and eliminates the drying process.

- It has the problem of joints, so you have to take care of the fit between panels.

- In the case of floors, tongue and groove is used.

- It is important to ensure that all batches of panels are the same shade as it can sometimes vary from the factory.

- It's also important to make sure it doesn't chip, as it can't be repaired.

- Melamine panels can be found in different sizes, but are generally manufactured in sheets of 2440mm x 1220mm and x1830mm.

- Thickness: The most common thicknesses of melamine panels are 16, 18, 19 and 25 mm.

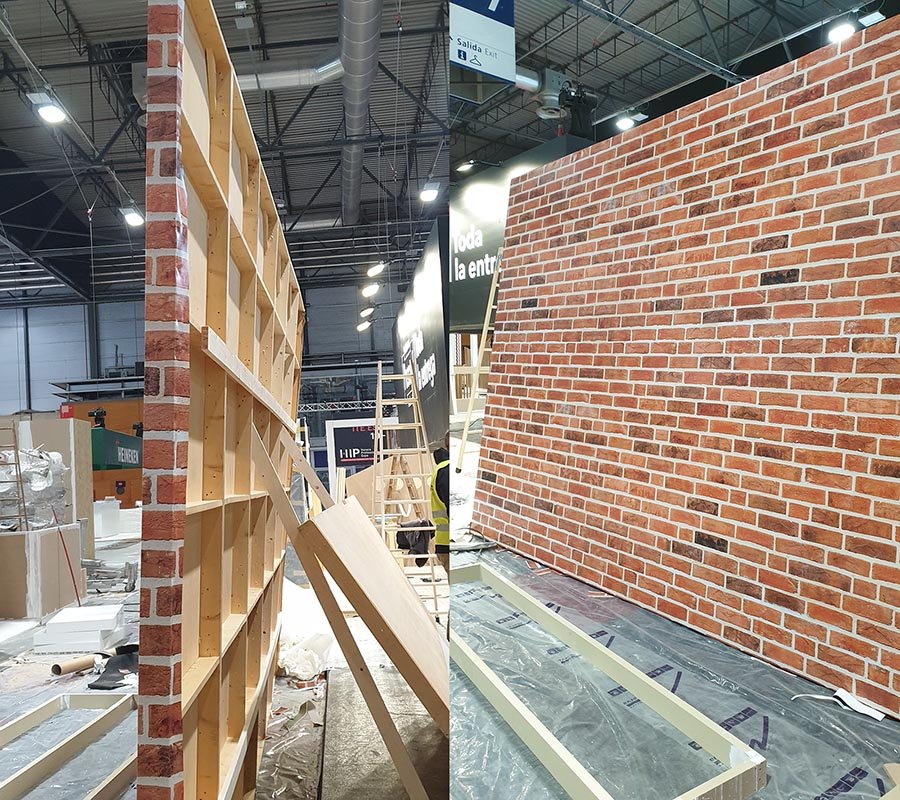

decorative wall panels

Decorative wall panels are an excellent option to create the effect you are looking for in the different spaces of your stand. They are often used as an imitation of brick, mosaic or sophisticated shapes.

- They are usually glued with ultra-resistant glue / double-sided tape to the support wall.

- There are all kinds of effects, from stone, brick or ceramic.

- The price, depending on the quality, ranges between 20 and 60 euros per square meter.

A- Trade fair carpet

- Made with a looped fiber construction with a flat surface.

- Often made from synthetic materials such as nylon or polyester.

- It is very important that it has a Bfl-S1 fire protection classification.

- It has a low profile and a more utilitarian look.

- Suitable for high traffic areas and can be easily replaced if damaged.

- It is usually cheaper than velvet carpet.

- It is very important that it has a Bfl-S1 fire protection classification.

B- Velor carpet

- Made with a cut pile structure, resulting in a soft, plush surface.

- They are often made from natural materials, such as wool or cotton, or synthetic, such as polypropylene or nylon.

- Available in fewer colors and patterns than the flat showroom carpet.

- It has a more luxurious look and feel.

- Suitable for more formal events or areas where appearance is important.

- May require more maintenance and care than flat show carpet.

- It is usually more expensive than the flat show carpet.

- It is very important that it has a Bfl-S1 fire protection classification.

C- Printed carpet

Printed carpeting is a great alternative when you want to place custom graphics or logos on a carpeted floor.

- Colors are a bit more muted than normal vinyl printing.

- The type of patterned carpet is not comparable to a velvet carpet, so you have to think that quality is sacrificed for the possibility of having a patterned floor.

- It is very important that it has the Bfl-S1 fire protection classification.

D- Carpet tiles

Carpet tiles are an excellent option for the flooring of a trade show booth. It is available in a wide variety of qualities and types. It is also an option offered by some furniture rental companies, since they reuse them. His hair is longer than that of the conventional carpet

- They are very easy to install and transport

- They are appreciated when it comes to repairing carpets damaged during the assembly or the fair itself;

- They allow a high level of creativity in the design of the floors;

- It is very important that it has a Bfl-S1 fire protection classification.

E- Cutout carpet

Carpet cutouts allow you to create creative designs on your floors without having to print them. They are an excellent alternative to make the floor one more point to take into account in the design.

- It allows all kinds of designs and creativity on the floors.

- It's a more expensive alternative, but it justifies itself when it comes to customizing your floors.

- It can be done with any type of carpet.

F- Exhibition stands with carpet directly on the floor

- It is the cheapest floor finish and can vary depending on the type of carpet used.

- It must be taken into account that when there is no platform, it is often necessary to pass the cables through cable ramps. In the case of requiring a water or compressed air installation, the size of the cable ramp must be adequate and it can make the installation difficult. stand circulation.

G- Melamine floors

- The melamine finish requires a platform. The platforms usually have a final height of 4 to 10 cm, including the melamine finish. They are joined by a tongue and groove system. An aluminum profile is placed around the entire perimeter to hide the joint between boards.

- Melamine floors allow all kinds of effects, from wood to concrete.

H- Technical floor + laminate tiles

- Technical floors allow a perfect finish.

- They have the advantage of being versatile when making changes to an already installed floor (for example, passing a new cable).

- It is a more expensive alternative to traditional melamine flooring, but the finish is far superior.

H- Laminate parquet

Laminate floors are easy to install and are usually click-locked, which means the planks snap together without the need for glue or nails.

Laminate floors can be installed by anyone with a basic knowledge of DIY, without the need to hire a professional, which can save money on installation costs.

Laminate parquet is a more expensive floor and better finished than melamine.

I- PVC vinyl floors

Vinyl pvc floors are an excellent solution for fair stands. They allow very interesting textures to be obtained at a reduced price, at the same time that they are very easy to install.

- With them excellent textures are achieved at a reasonable price. There are all kinds of finishes and effects.

- They are installed in the form of tiles or rolls, which are two different types of vinyl. The tiles are of better quality.

- They can be installed without a floor as long as the vinyl is on a roll; it is a higher quality alternative to “straight to the floor” carpet at a lower price.

¨traversable¨ type vinyl must be used so that it does not disintegrate with the movement of people. These vinyls have a laminate that gives them greater resistance to footsteps. It is more complicated to place than vinyl on the wall, you have to use water to avoid wrinkles. It is traversable vinyl and is much more expensive than normal vinyl. Depending on the case, normal laminated printed vinyl can be installed.

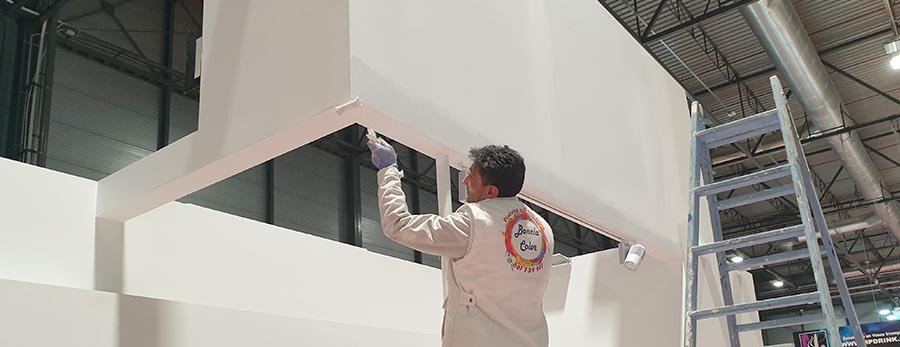

paint finishes

One element to take into account with painting is to respect the corporate color. Although the paint is prepared based on Pantone, ral, or cmyk, many times the colors have to be touched up or chosen from the palette of the machine that prepares them taking into account the light of the pavilions. Reds especially can often appear orange when exposed to natural light. We recommend that you do a paint test before starting the assembly to verify that the color corresponds to your brand.

A- Water-based plastic paint

As we have already said, water-based paint usually gives a porous finish that does not favor the placement of the graphic. Special care must be taken with colors, since the most vivid pigments increase porosity and make adhesion even more difficult. How to prevent graphics from peeling off? It is always better to choose melamine, but if you decide to paint with water, either for a budget or to try to choose a specific color, the important thing is to use ultra-tak graphics (this must be discussed with the sign maker, or with the builder if it is key in hand) On the other hand, it must be taken into account that some colors get very dirty, such as black. For this reason, it is always necessary to check the paint at the end of the assembly. Don't forget to check that the painter has any traces of paint until the last moment, when a color runs out it is difficult to prepare a new one and it can be impossible in a weekend.

- They are excellent in terms of drying, taking much less time than oil paints.

- It is important to let it dry for at least 6 hours if graphics are going to be placed on top. The optimum is 24 hours.

- It is necessary to wait 3 hours between coats of paint.

- Pigmented colors offer less surface area for the graphic than white.

- Red and blue colors may appear lighter depending on the light in showrooms.

B- Lacquered

Lacquer is the best possible finish for a stand, but it is very expensive. It is often used by brands and companies that are going from strength to strength because the budgets are very high. Lacquered panels require joints made in the workshop, as they cannot be painted on site. At the same time, it requires a perfect packaging of each panel, because a blunting cannot be fixed. It is usually painted in paint booths. Often, the walls of the stand are painted with water-based paint or melamine, while the elements with which the public interacts are lacquered. Tip: if you make a booth abroad, do not make lacquered walls. Your supplier, if it is not local, will not be able to replace the depainted parts.

- Lacquer is a very expensive finish, which is why it is normally only used on furniture, avoiding large surfaces.

- A perfect finish requires painting in a spray booth, so if it does chip there is no way to repair it perfectly.

- It is important to take care of the cleanliness of the surfaces, since the fingers are marked.

C- Synthetic acrylic paint

Glossy or matte synthetic or acrylic finish is not usually used for walls, since it not only leaves a very strong odor, but also takes much longer to dry. This option is usually reserved for painting metallic elements such as pillars, supports or legs.

- Lacquer is a very expensive finish, which is why it is normally only used on furniture, avoiding large surfaces.

- A perfect finish requires painting in a spray booth, so if it does chip there is no way to repair it perfectly.

- It is important to take care of the cleanliness of the surfaces, since the fingers are marked.

Signage finishes

The finishes of the signs can affect the quality of the stand and, therefore, must be taken into account. Once the graphics are in place, it is often necessary to touch up the edges or embellish the seams. Let's discuss these details:

A- Printed vinyl

- The printed vinyl can be detached so it must be placed on a dry support, both the cut printed vinyl and the printed vinyl that covers the entire wall.

- There is no need to put laminated vinyl on the walls as it will sit for a few days and will not be affected by use.

- It is necessary to place double-label vinyl and avoid placing the vinyl on pigmented colors because its adhesion is less.

- It must be placed with a spatula and water to avoid bubbles, although there are professionals who can do it perfectly with just the spatula.

B- Frontlit canvas and stapled textile

The stands made with stapled textile are a solution to painting, since it is not necessary to paint the walls. If you are going to use textile it is important that it be blackout, so that the color of the panel does not show. Many times carpenters use recycled boards that have the color of other supports. This finish usually has wooden plugs at the ends of the canvases to hide the staples.

- Printed canvas and printed textiles stapled to joinery require finishing with a finial.

- It is very important to take sandblasting into account when printing as there may be variations in the woodwork that leave unprinted white edges.

- In the case of textiles, the blackout type should be used. This is not necessary in the case of canvas frontlit.

C- Corporeal 3d

The corporeal 3d logos can be made of different materials, but solid pvc painted with acrylic is normally used, and as a more economical option, porexpan painted with water-based plastic paint. This second option is less used every day thanks to the rise of three-dimensional cutting plotters, since its finish is more rustic. However, it is a good option that has been used in the industry for 20 years and allows all kinds of imitation finishes to be achieved.

Expanded polystyrene or extruded polystyrene foam

- Expanded Polystyrene (EPS) logos are lightweight and durable, making them ideal for a variety of applications.

- For best results, water-based paints are generally preferred for painting EPS foam as they are less likely to damage or deform the foam. In addition, water-based paints are usually more environmentally friendly and easier to clean than solvent-based paints.

- EPS logos are typically made using a hot wire cutter or CNC mill, and can be customized to almost any shape or size.

3d logo with led lighting

Logos cut with a cutting plotter are one of the most used options today, since they do not require manipulation and have an almost perfect finish. Normally the thickness is 2 cm and if thicker pieces are needed, the plates are joined. It can be painted with acrylic paint.

LED corporeal logos have become fashionable at the fair in recent years. What was previously solved with neon is now immensely more accessible and easy to work with. The letters are hollowed out on the back to put the led. The price is not cheap but they guarantee a very important graphic impact.

Don't miss the next chapter of this exciting adventure!

I hope this finishing guide is useful to you. In the next article I will talk about modular stands and sustainability at fairs.