Types of signage for exhibition stands

First of all, we are going to review the different types of signage that are usually used for fair stands and their characteristics. It is important to know them since the person who makes the graphic design has to prepare the graphic according to the format in which it is going to be printed.

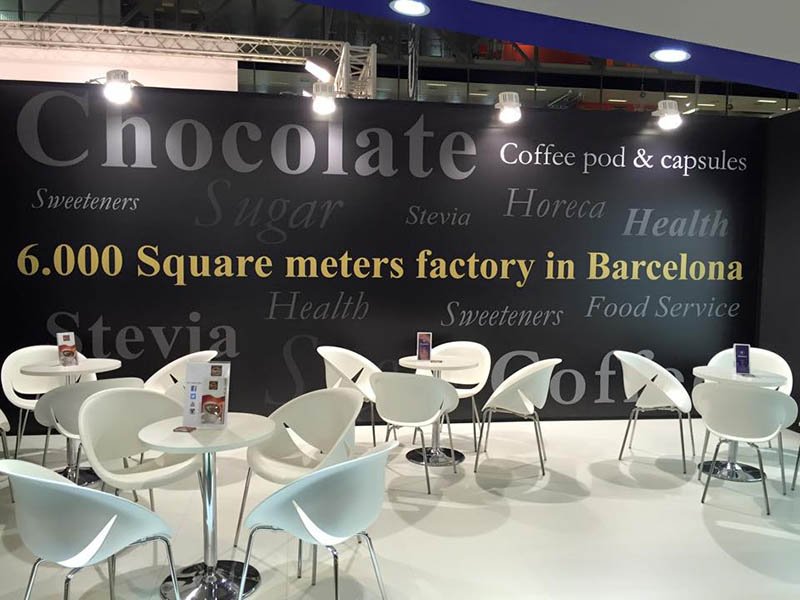

Self-adhesive printed vinyl

Printed vinyl is a white adhesive on which the desired design is printed. It is usually used to print images with different colors and gradients, since, unlike cut vinyl, it has no color or shape restrictions.

Important aspects to consider when installing them

- Check that the print files have the correct bleed (you can follow the guide below in the post);

- Verify that the graphics have the necessary safety indentation (a recess of the images and texts of at least 10 cm towards the interior of the graphic piece). This is done because if there is any adjustment error in the carpentry there is room to paste them anyway forms (this is very useful if you are outside your country or the provider is foreign and does not have immediate response capacity);

- Check and try that the most complex parts of the graphic do not coincide in the union of the printed strips (this depends on the printing carriage of your supplier);

- If you are going to place a self-adhesive printed vinyl on painted wood, it is important that it have extra adhesion (ultra-tack). There are printed vinyls with less adherence than others, you have to discuss this point with your provider and if possible include it in your contract.

- If you are going to put vinyl on melamine, keep in mind that they are sometimes difficult to remove and can damage a piece of carpentry when removing it if you are going to reuse it later. This is the best option for the perfect self-adhesive vinyl.

- Although it is true that the vinyl can be placed by a single person, two people are ideal to optimize time and ensure that there are no errors.

- Keep in mind that if you make prints with a white background, this color will contrast with the white color of the wood, so it is always better to vinyl the entire set, or use dies for the areas with a white background.

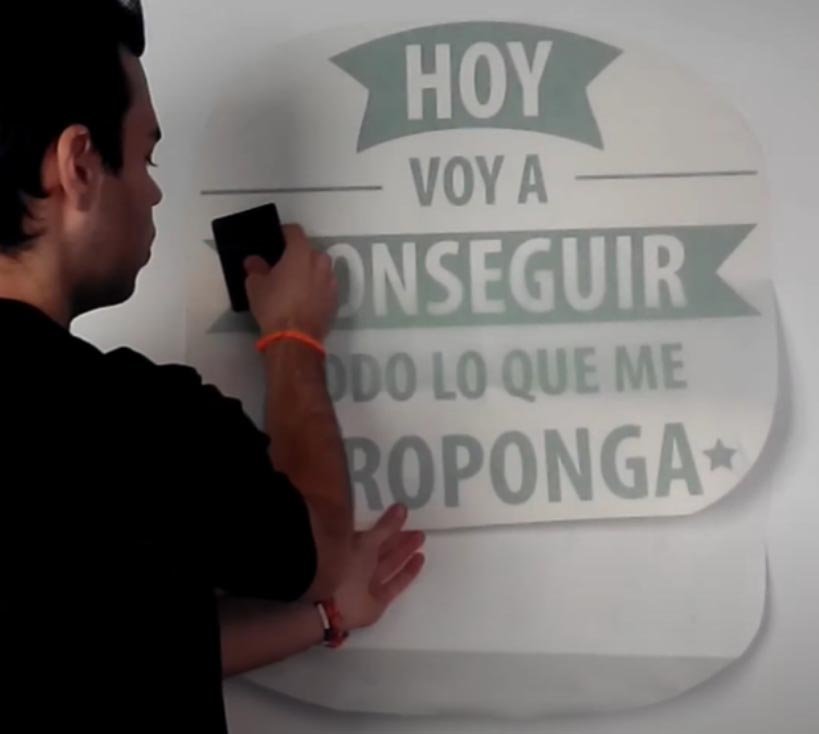

- There is a way to paste lettering, it is important that you know it. I recommend you this video where they explain how to do it. Even if you are not going to do it, it is important that you see that they do it correctly;

- The quality of a print depends to a large extent on the number of passes that the plotter makes.

In vinyl printing, the number of passes required to achieve accurate colors and contrast with the original will depend on several factors, such as the quality of the original image, the print resolution, the quality of the ink used, among others.

Generally, at least 8 passes are recommended to ensure the most accurate colors and adequate contrast. However, more passes may be necessary if the original image is highly detailed or if high color accuracy is required.

Cutting vinyl

It is an adhesive vinyl of a certain color, which is cut with the desired silhouette. It is mainly used for logos, letters, figures, car wraps, etc. The cut vinyl has the limitation that it can only have the color of the vinyl roll that is cut. It is possible to make a composition with material from several rolls on the same support, but today it is cheaper to use die-cut printing (opos) than this.

Important aspects to consider when manufacturing and installing them

- Please note that the colors are vinyl colors so they may differ from your brand colors. Although your supplier may suggest a very similar vinyl color, it is never comparable to die-cut printing.

- If you use white or black the result is very good and cheaper. you can also use gray.

Please note that if you are going to stick these graphics on painted walls (which is never recommended) it is important that they have a double stick. Plastic water-based paints with color pigments offer less adherence than white walls. - In this case it is not necessary to leave any type of graphic indentation.

- When the color is white, it must be indicated in the files, since when they are sent the outline of the shape is not seen in the computer preview.

- It is important that the minimum letter size is 1 cm and that the lines are not thinner than 2 mm.

Printed Vinyl + (OPOS) (trimmed)

OPOS Contour Cutting Alignment System is short for "Optical Positioning System" It is used for cutting printed logos. Unlike cutting vinyl, in which you have to choose the color of the vinyl to be cut, any printed figure can be cut, including logos or any graphic element. In this way it is not necessary to know the pantone of the logos or of any color since the graphic file that is printed already contains it.

Important things to consider when producing and installing them

- In this case it is not necessary to leave any type of graphic indentation.

- It is important that the minimum letter size is 1 cm and that the lines are not thinner than 2 mm.

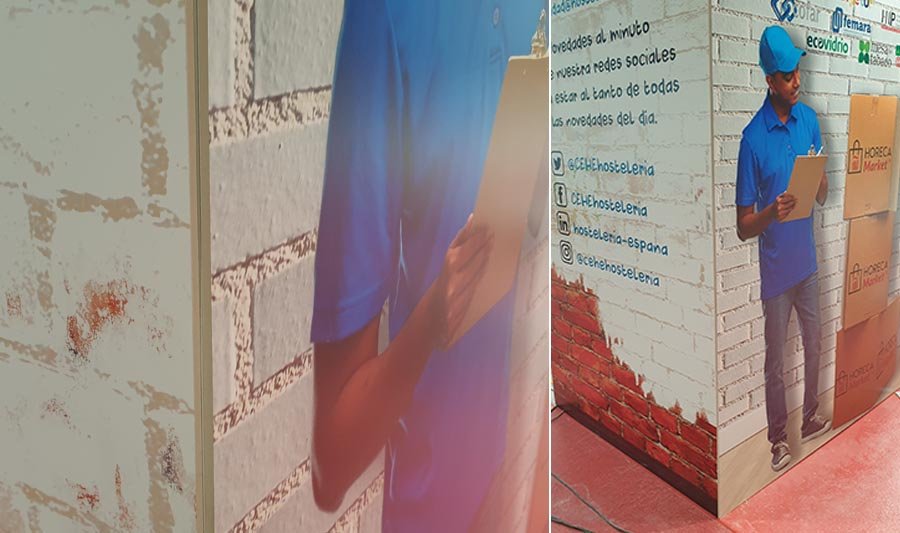

Printed Textile

Digital textile printing is an innovative and modern technique that consists of direct printing on fabric using specialized machines for this function. Textile printing is used both in modular systems and in craft stands. The advantage of the textile is that in addition to being lighter to transport, it practically does not generate wrinkles.

In modular stands, tensioning is used instead of rigid walls. In artisan stands it is usually stapled to the walls. In this case, it must be taken into account that it is necessary to place plugs to cover the staples. With textile printing it is not necessary for the stand walls to be perfectly finished as they will be covered by the fabric.

There are different qualities in textile printing:

- Latex inks, (soft and water). The print is impregnated into the fabric.

- UV inks The print is placed on the fabric.

- Sublimation. They adhere to the fabric by heat and are water-based. It is the best print quality due to the contrast and strength of its colors.

Important aspects to consider when producing and installing printed textiles

- If you are going to place the fabric covering the walls of the booth, it is important that you make it blackout (opaque black back) otherwise any color that may be on the walls could show through if it is not planned to paint them.

- Regarding the bleeding of the images, it is important to increase it by 5 cm per side with respect to the bleeding used in self-adhesive vinyl.

frontlit canvas

Frontlit 510 g/m2 canvas is the most widely used material for printing low-cost banners and billboards. It can be stapled to the carpentry, hung or tensioned by means of eyelets. They are also used hanging from the ceiling of the fair with a counterweight. This option is dangerous because if it is not done very well it can wrinkle.

Important things to consider when producing and installing them

- Regarding the bleeding of the images, it is important to increase it by 5 cm per side with respect to the bleeding used in self-adhesive vinyl.

- Depending on the size of your carrier's print carriage, be aware that your frontlit banner may have a seam at the junction of the fabrics.

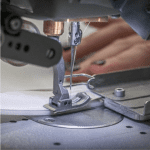

- When you make hanging canvases you must make sure that the seams have not been sewn by hand, but with a suitable machine for this purpose (with a feed carriage). This is the only way to prevent the canvas from wrinkling when hanging. You should also keep in mind that the larger the canvas, the more likely it is to wrinkle. You can find more information about these machines here: Automatic/Matic Stitching Machine

Corporeal logos for stands

A 3D logo is one that uses three-dimensional elements. It is manufactured in painted MDF, porex, methacrylate or pvc (among others). The thickness varies according to the material, between 5 mm and 3 cm. can be backlit

Important things to consider when producing and installing them

The corporate logos (3d) are manufactured in different finishes according to budget or function. The most used are:

- Acrylic: Acrylic is a popular material for 3D logos due to its durability, versatility, and ease of molding. They can be laser cut and engraved to create precise shapes and intricate details.

- Styrofoam: Styrofoam is an inexpensive option for creating 3D logos. It can be cut to custom shapes and coated with a variety of materials to give it a more realistic finish.

- Lacquered MDF: MDF (Medium Density Fiberboard) is a composite material made from compressed wood fibers and is commonly used to make 3D logos. First, the MDF is cut to the desired shape using a table saw or CNC router. It is then sanded and lacquered to give it a smooth, glossy finish. Intricate details can also be added using engraving or printing techniques.

- Cork: Cork is a lightweight and sustainable material that is commonly used in the manufacture of 3D logos. First, the cork is cut to the desired shape using a table saw or laser. It is then carved and painted with acrylic paint to create detail and a durable finish. Cork logos can also be layered and glued to create a deeper 3D effect.

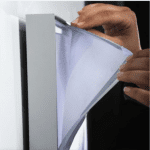

Backlit fabric displays

Backlit fabric is a special type of textile that facilitates the passage of light and allows colors to be enhanced. The backlits can be manufactured with a modular system or by hand. In custom-made backlits, the fabric is stapled to the drawer that contains the lighting. That is why they are usually finished off with a frame of wooden slats to hide them.

Important things to consider when producing and installing them

- To guarantee the best image quality it is advisable to use sublimation textile printers. In this way, colors remain vivid and contrasted.

- If the graphic is to be placed in a custom light box, lids must be provided to cover the staples.

- The lighting intensity must be high, so it is important that the LEDs used are 20w.

- There are lighting systems for light boxes that are placed around the perimeter of the frame. In this case, the intensity of the LEDs is even higher. The result is very good.

- Regarding the number of passes that the plotter must make, for transparent or backlit vinyl, 16 or 24 passes are recommended, depending on whether you use the overprint to backlit or not.

Trevira fabric

The semi-transparent fabric (trevira) is perfect for creating translucent spaces. Thanks to its low density point, it allows viewing both images and the interior of the rooms it covers. The color is usually a little duller than the normal print.

Important things to consider when producing and installing them

- To guarantee the best image quality it is advisable to use sublimation textile printers. In this way, colors remain vivid and contrasted.

- The translucent graphic allows an airy and permeable appearance, allowing the visualization of all sectors of the stand without blind barriers.

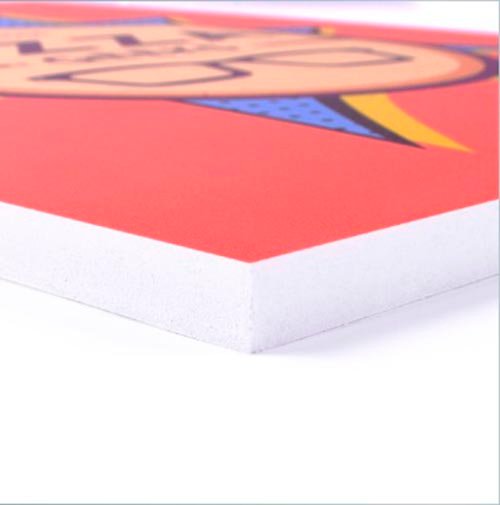

Foam board (foamex)

Foam board is a semi-rigid pvc support with an integrated printed film. Allows optimal rigidity for hanging lightweight signs and banners on the wall. In case of looking for a more rigid support, Forex should be used. Available in 3/5/10 mm thickness.

Important things to consider when producing and installing them

Lightweight: Foamex is a lightweight material, which makes it easy to transport and install. It is especially useful in fairs and exhibitions, where mobility is an important factor.

Durable: Foamex is a durable and weather resistant material. It is resistant to moisture, scratches and sunlight, making it ideal for long-term exhibitions.

Easy to cut and mold: Foamex can be cut to any shape and size with simple cutting tools such as knives, scissors or a CNC router. It can also be easily bent and shaped to create three-dimensional shapes.

Easy to print: Foamex is a material that can be directly printed using digital or screen printing techniques. It is compatible with UV inks, resistant to fading and scratches.

Variety of thicknesses: Foamex is available in a variety of thicknesses, from 1mm to 20mm, making it suitable for a wide range of applications. The thicker panels can be used to create freestanding stands, while the thinner ones can be used for wall charts or information panels.

Walkable printed vinyl

Printed flooring vinyls are a popular choice for signage and advertising in commercial and event spaces. Walkable vinyls allow people to walk on them without peeling or damaging them.

Important things to consider when producing and installing them

Most flower vinyl graphics consist of 3 important elements:

- The Base Vinyl Layer: The base vinyl layer is the flexible substrate on which the images are printed.

- The Non-Slip Laminate Coating: Sometimes referred to as a matte mask, the non-slip laminate coating protects the design from hazards such as slipping, scratching, fading, and skid marks.

- The strong adhesive layer: The adhesive layer sticks the sticker to the floor during installation.

Frosted Faux Vinyl (Printable)

It is used to give offices privacy without completely closing them off. It is an economical alternative to foamed glass. It can be printed in color or cut.

Important things to consider when producing and installing them

- Thickness: Frosted vinyl is available in different thicknesses, but it is generally thinner than other types of vinyl.

- Adhesion: Frosted vinyl has an adhesive layer on the back that adheres to the glass surface. It is important to ensure that the surface is clean and free of dust and grease for optimal adhesion.

- Translucency: Frosted vinyl is translucent, which means it allows light in, but often reduces visibility through the glass.

Forex

Forex is a rigid pvc (unlike foamex, which is softer) that allows direct printing on its surface. It weighs more than foamex but has excellent rigidity that makes it the most widely used self-supporting printing method. It comes in 3/5/10mm formats.

Important things to consider when producing and installing them

Some of the technical characteristics of printed Forex are:

- Light: Printed Forex is a very light material compared to other materials such as wood or metal, which makes it easy to transport and handle;

- Resistant: The printed Forex is resistant to humidity and UV rays, making it suitable for outdoor use;

- Easy to print: Printed Forex can be easily printed using a wide range of printing technologies, including digital printing;

- Versatile – Printed Forex can be easily cut and shaped, allowing for custom designs.

Size and weight: Make sure that the size and weight of the printed Forex are suitable for the booth and that you can easily install and remove it.

Fixing: Make sure that the printed Forex is well attached to the stand to prevent it from falling or moving during the event.

Guide for preparing graphics for stand signage

When preparing the final graphic material for a stand it is very important to make clear the size of each graphic, its support and the measurements of the placement. When you send the files to your turnkey stand builder, you think that you are working with a professional and that the final result will be the same as in the renders: this is not always the case. Many companies leave the signage in the hands of their sales representatives, without a technician being involved in the process. This means that the printer receives files that are not prepared for an optimal result. This is how some of the following errors occur, which we will help you avoid;

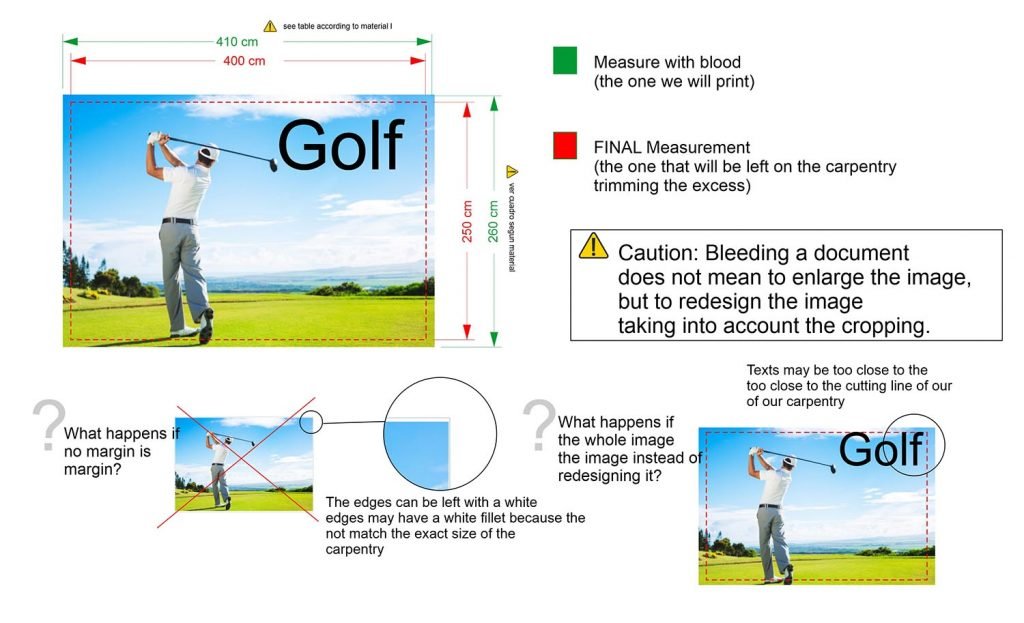

Example of preparation for large format banners

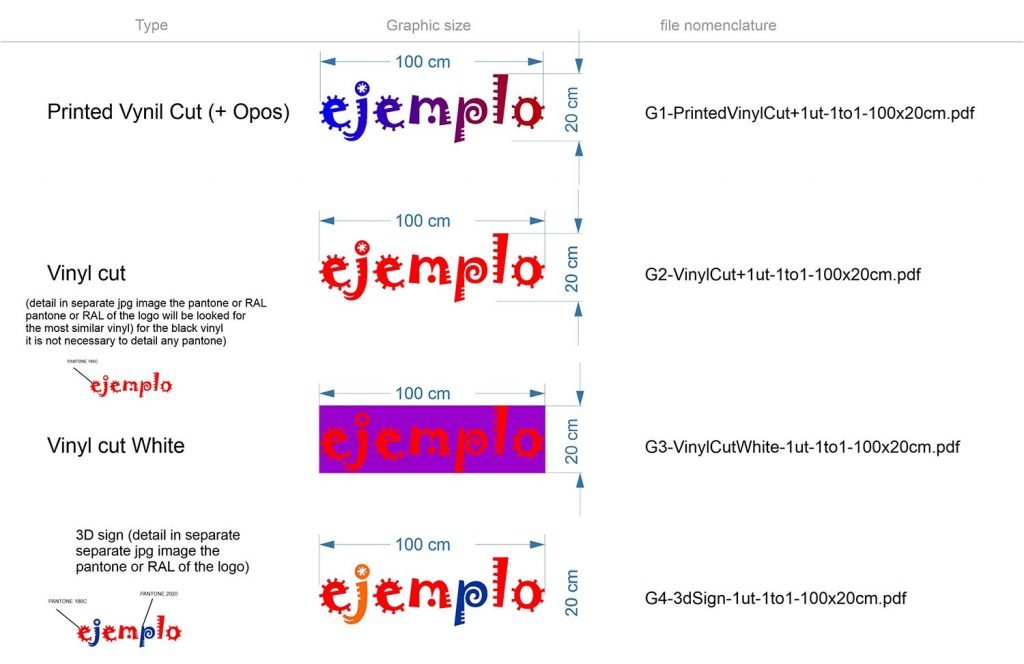

Vector graphics preparation example

In summary, what you should keep in mind

in each graphic format:

| graphic type | Blood | Example of 2x2 graphics, final size | File format | minimum resolution | Minimum delivery time |

|---|---|---|---|---|---|

| Printed self-adhesive vinyl | 5cm each side | 2.10x2.10m | pdf/tiff/jpg/tga | 72 dpi at actual size. In case of a very large format, save to 50 or 25% and specify it in the file name. Increase the resolution based on the rescaling of the file. | One month before the fair |

| Cutting vinyl | No bleeding is needed. The size of the graphic piece must match the actual size of the logo. In case it is white, put a green background, and detail it in the file. | 2.00 x 2.00m | pdf/ai/eps/cdr (must always be vector) Do not send image formats | Vector | One month before the fair |

| Printed vinyl + OPOS | No bleeding is left. The size of the graphic piece must match the actual size of the logo. | 2.00 x 2.00m | pdf (must always be vector) Do not send image formats | Vector | One month before the fair |

| printed textile | 10cm per side | 2.20 x 2.20m | pdf/tiff/jpg/tga | 72 dpi at actual size. In case of a very large format, save to 50 or 25% and specify it in the file name. Increase the resolution based on the rescaling of the file. | One month before the fair |

| frontlit canvas | 10cm per side | 2.20 x 2.20m | pdf/tiff/jpg/tga | 72 dpi at actual size. In case of a very large format, save to 50 or 25% and specify it in the file name. Increase the resolution based on the rescaling of the file. | One month before the fair |

| 3d corporeal | No bleeding. The file must be sent with its corresponding colors, detailing the pantone of each color in the mail or we transfer it. | 2.00 x 2.00m | pdf (must always be vector) Do not send image formats | Vector | One month before the fair |

| backlit film | 10cm per side | 2.20 x 2.20m | pdf/tiff/jpg/tga | 72 dpi at actual size. In case of a very large format, save to 50 or 25% and specify it in the file name. Increase the resolution based on the rescaling of the file. | One month before the fair |

| lona trevira | 11cm per side | 2.20 x 2.20m | pdf/tiff/jpg/tga | 72 dpi at actual size. In case of a very large format, save to 50 or 25% and specify it in the file name. Increase the resolution based on the rescaling of the file. | One month before the fair |

| Foam (foamex) board | 2cm per side | 202x202m | pdf/tiff/jpg/tga | 150 dpi | One month before the fair |

| Frosted vinyl (printable) | 2cm per side | 202x202m | pdf/ai/eps/cdr (must always be vector) Do not send image formats | 150 dpi | One month before the fair |

In this post I have tried to give you a general idea of the different graphic supports used in European exhibition spaces. If you want to delve a little deeper into the subject you can also check the following post in which I talk about the different graphic finishes.

Lastly, if you think I have forgotten some important support or technique, I would appreciate it if you could leave it in the comments 😉

Don't miss the next chapter of this exciting adventure!

I hope this post about Furniture for fair stands has been useful to you. In the next post I will talk about an element that often ends up defining the aesthetics of your stand as well as its comfort for your potential customers: The furniture.